![]()

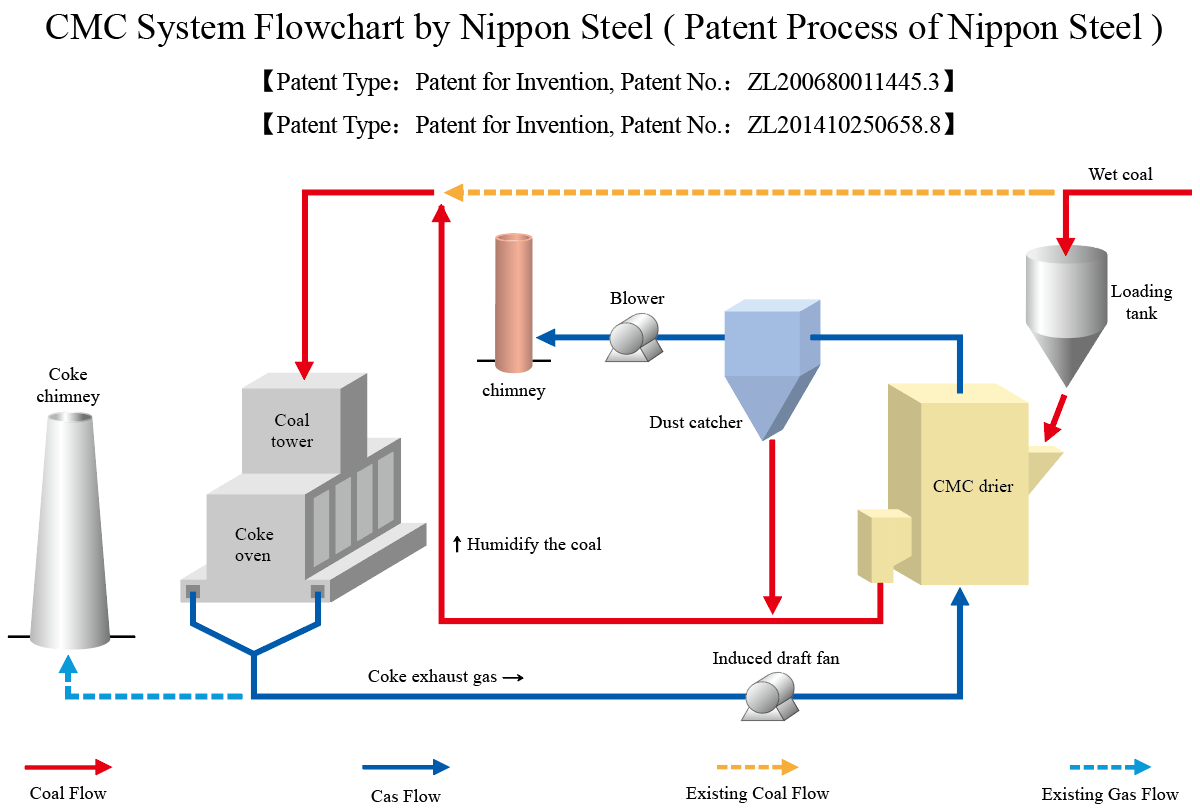

CMC is a kind of device that will usually reduce the coal’s moisture from 10% to 6% by drying before the coal will be charged to the batteries. Using dry coal can get considerable economic benefits.

All steel plants of Nippon Steel Corporation have been equipped with CMC device. For the time being, the CMC system have adopted fluidized bed. Since it was introduced to Muroran Works in 1996, the operating has been going smooth, and it has been making constant benefits.

1. Less investment

It adopts fluidized bed with direct heating, which makes less investment and miniaturization in device structure to come true.

2. Low operating cost

To use flue exhaust gas of coke-oven as heat source for CMC, no other fuels are required.

Maintenance for CMC becomes much easier due to less transmission parts and simple structure of device.

3. Rich operation performance

With many years of operation practice, operation technique for CMC has been established and possessed. And we also have rich practical experiences in environmental protection measures.

(Estimated as per the processing capacity of 180t/h, and coal moisture is dried from 11% to 5 %.)

1. Production capacity is increased by 10%

The output of coke oven is increased greatly by improving coke density and shortening coking time.

2. Energy is saved by 10%

The dry distillation heat to be consumed can be saved by decreasing coke moisture.

3. Coke strength is increased

Coking ability of coal is improved by increasing coal density, which greatly increases the strength of coke.

4. Stability of production operation is realized.

Coke production can be stabilized by controlling the coke moisture.